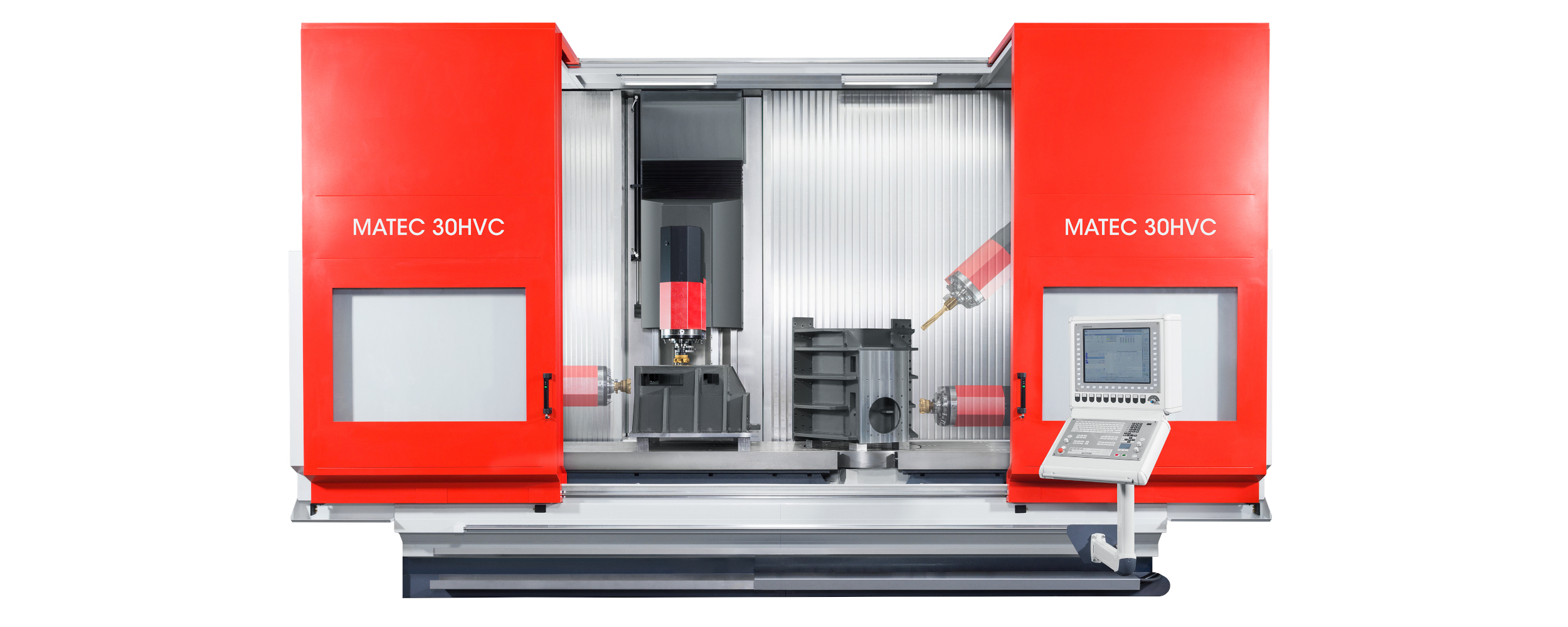

MATEC 30HV - Available from stock

with Control Unit SINUMERIK ONE

Basic equipment:

- 1-Axis NC swivel head, swivel radius 300 mm, swivel angle +/- 105°

- Motor spindle 15,000 1/min., 30 kW, 191 Nm

- Tool holder HSK A63

- 60 tool places

tool Ø max. 200 mm, tool length

max. 460 mm, tool weight max. 10 kg,

shuttle changer - NC rotary table with face plate Ø 800 mm, integrated into the machine table, rotation speed max. 25 1/min., with worm drive

- Rapid traverse 48 m/min in all axes

- Working area, fully enclosed, with roof, ergonomic machine front in curved design for optimal accessibility of the machine interior

- Internal coolant supply 20 bar / tank capacity 900 l

- 3D radio touch probe

Options - if the production status of the machine allows:

- Preparation additional tool magazine

- Additional tool magazine with 220 places

- Additional control panel

- Mechanical mist collector CMC 1500 J-SP

- Partition wall for double work station system for Y-axis up to 800 mm

- Position of partition wall = 200 mm

- Tool breaking control and measuring of tool length

- Tactile tool breaking control

- RTS tool setter system for measuring, checking and tool breakage control of cutting tools in the machine

- Collision monitoring UT-Tec