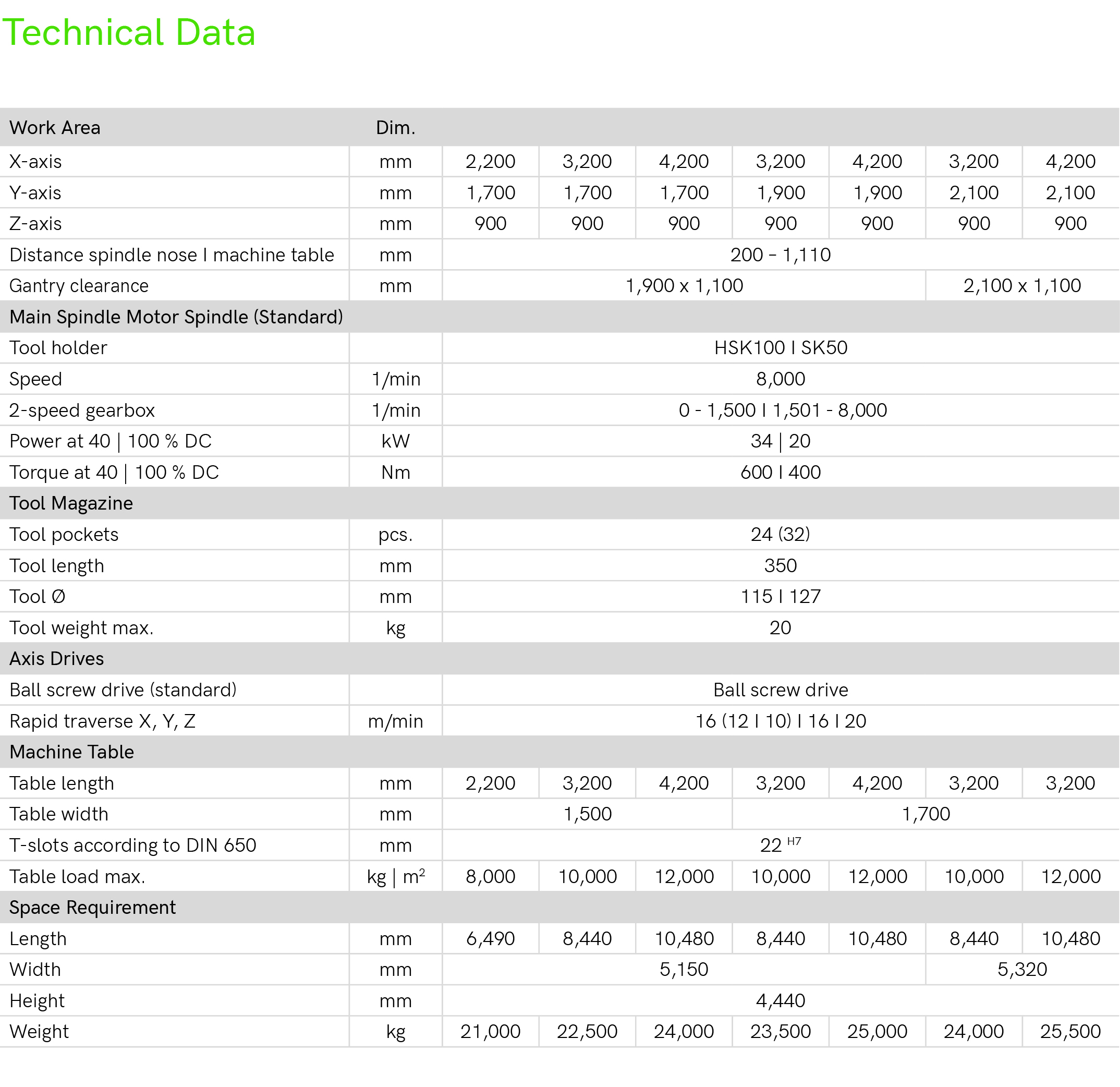

MATEC GPC - Gantry Centre

Performance class HSK100

Vertical gantry machining centre with fixed gantry and

moving machine table as X-axis. Y- and Z-axis are built

on the gantry girder. All base structures of the machine

consist of high-quality heat treated cast iron. The

machine structure having been calculated by means

of Finite Elements Analysis (FEA) is perfectly ribbed

and guarantees extreme rigidity.

The gantry girder and the two vertical columns are

made out of one piece (Y = 1,600 mm). The machine

is equipped with precise and high-capacity linear guides

in all three axes.

The axes are driven by ball srews.

All moving parts of the machine are lubricated by an

automatic central lubrication system.

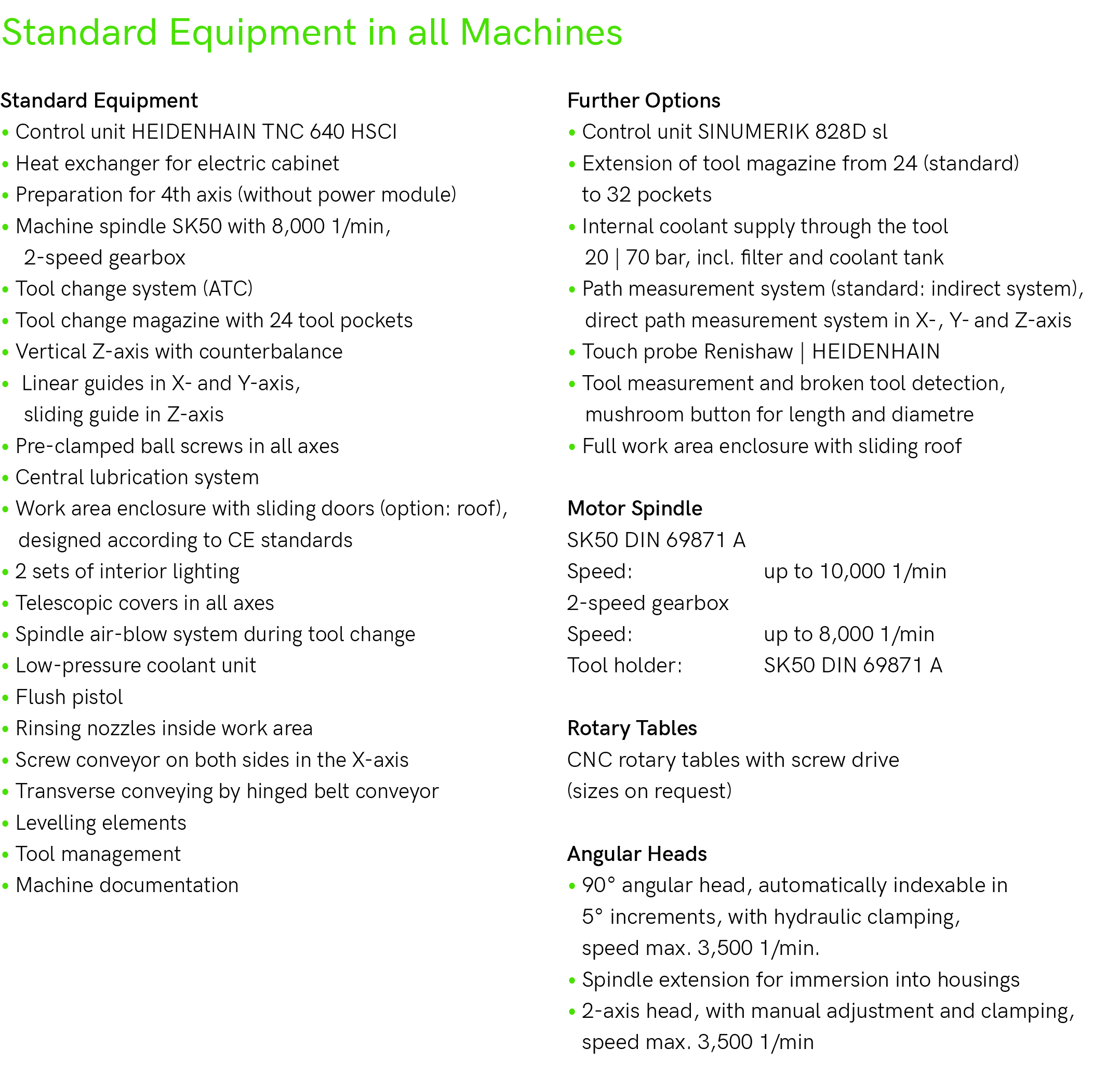

The tool magazine and tool changer are mounted in

parallel in the X-axis and are detached in the work area.

Tools are being changed in a fixed X-position in the topmost

Z-axis position.

Tool change system with chain magazine and dual

gripper. To change the tool which is lying horizontally

in the chain magazine it is being brought into vertical

position. At the same time, the dual gripper picks the

new tool as well as the one sitting in the spindle and

changes the tools by making a 180° turn.

High cutting performances in almost every material can

be achieved by means of the built-in high-power spindle

with 2-speed gearbox.

The ball bearings are lifetime grease-lubricated.

Additional equipment such as full work area enclosure

with roof, telescopic covers in all axes, coolant unit

with rinsing nozzles and bed rinsing as well as a chip

removal, perfectly adapted to the performance class,

are completing the machine.

Due to the numerous options, the machine can perfectly

be customized.