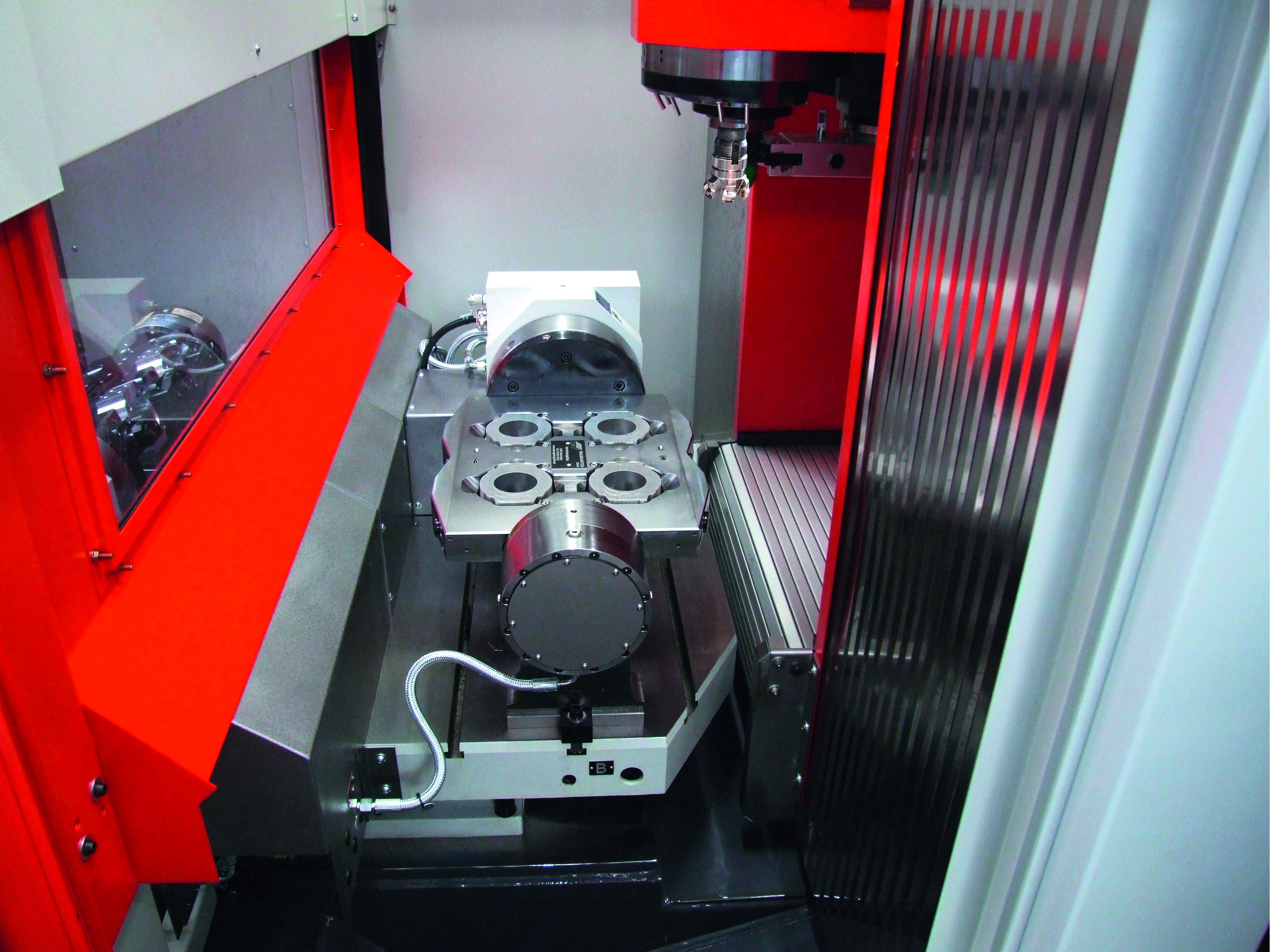

MATEC 30S - Two work areas. Loading and unloading during machining

3-axis machining centre with swivel table

Tool change directly above the workpiece

Pallet change in approx. 4 seconds

Ideal concept for manual and automatic loading

Additional rotary tables or swivel bridges with counter

bearing enable multi-sided machining. Furthermore,

special tools such as multi-spindle heads and angular

drilling heads as well as oversized tools can be set up

economically via pick-up stations.

Rotary distributors for clamping hydraulics, pneumatics

or vacuum integrated in the swivel table enable complex

fixtures with multiple clamping or different clamping

sequences.

Work area 1: Loading station.

Design with rotary table, fixture bridge and counter bearing

Work area 2: Machining station.

Multi-sided machining in one clamping position