Automation solutions - The ideal combination of high-productivity series machines and effi cient automation

30SHV | 30S | 30SD

The machines of the MATEC swivel table series solely

consist of the modules of our sturdy long-bed machine

series. In series production, they are therefore preferentially

used where high cutting capacity is required and

for the end machining of long components.

The machine is offered in three basic versions:

- MATEC 30SHV with swivel head

- MATEC 30S Single-spindle version with fixed head

- MATEC 30SD Double-spindle version with fixed head

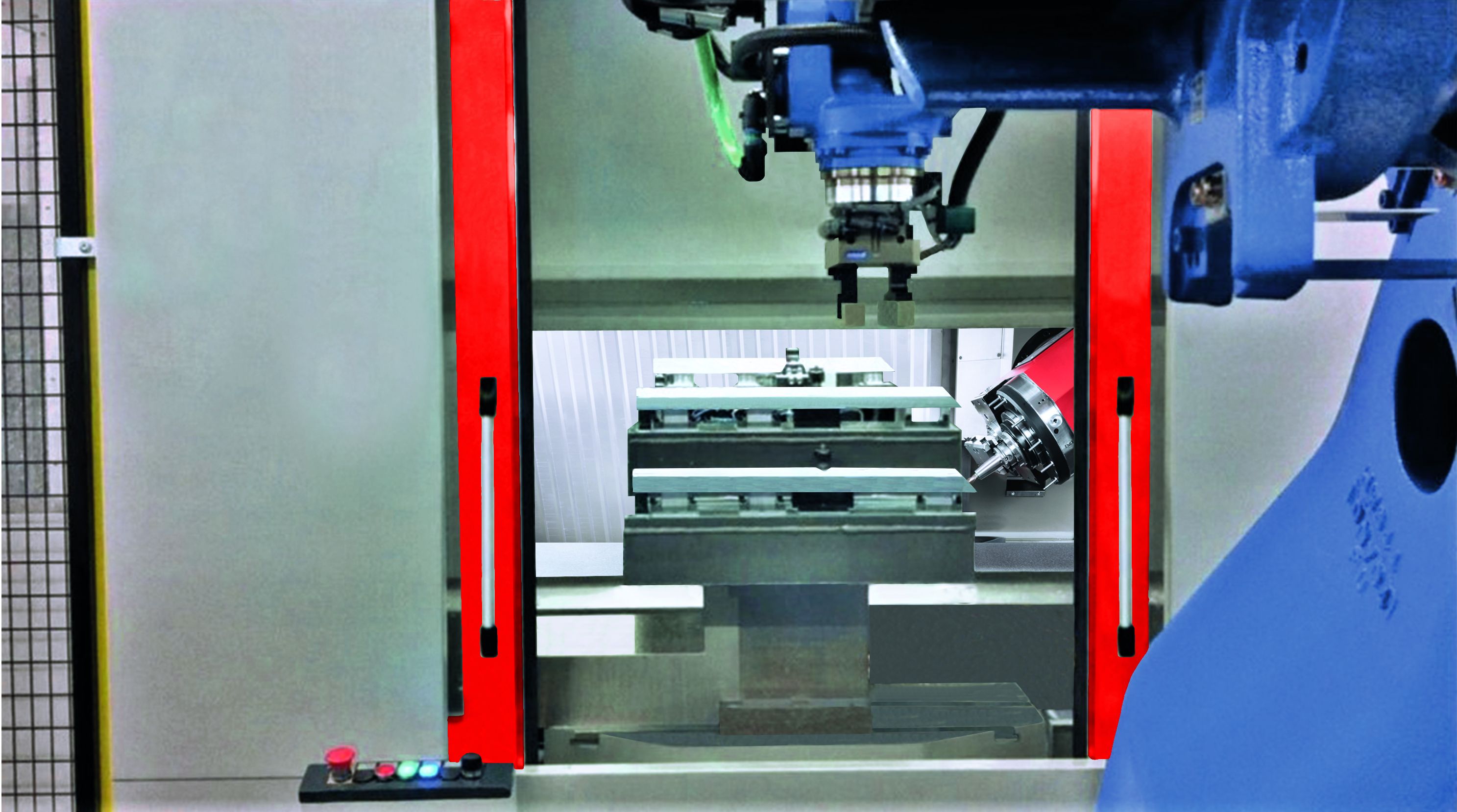

For all machine versions, the production principle of

the MATEC swivel table series is based on a 0–180°

pendulum swivel table with two separate work areas.

The work area is changed by a 180° rotation of the

swivel table.

A lifting door with safety glass separates the machining

areas. This design enables loading and unloading to take

place during machining while the machine is producing

in the other machine area.

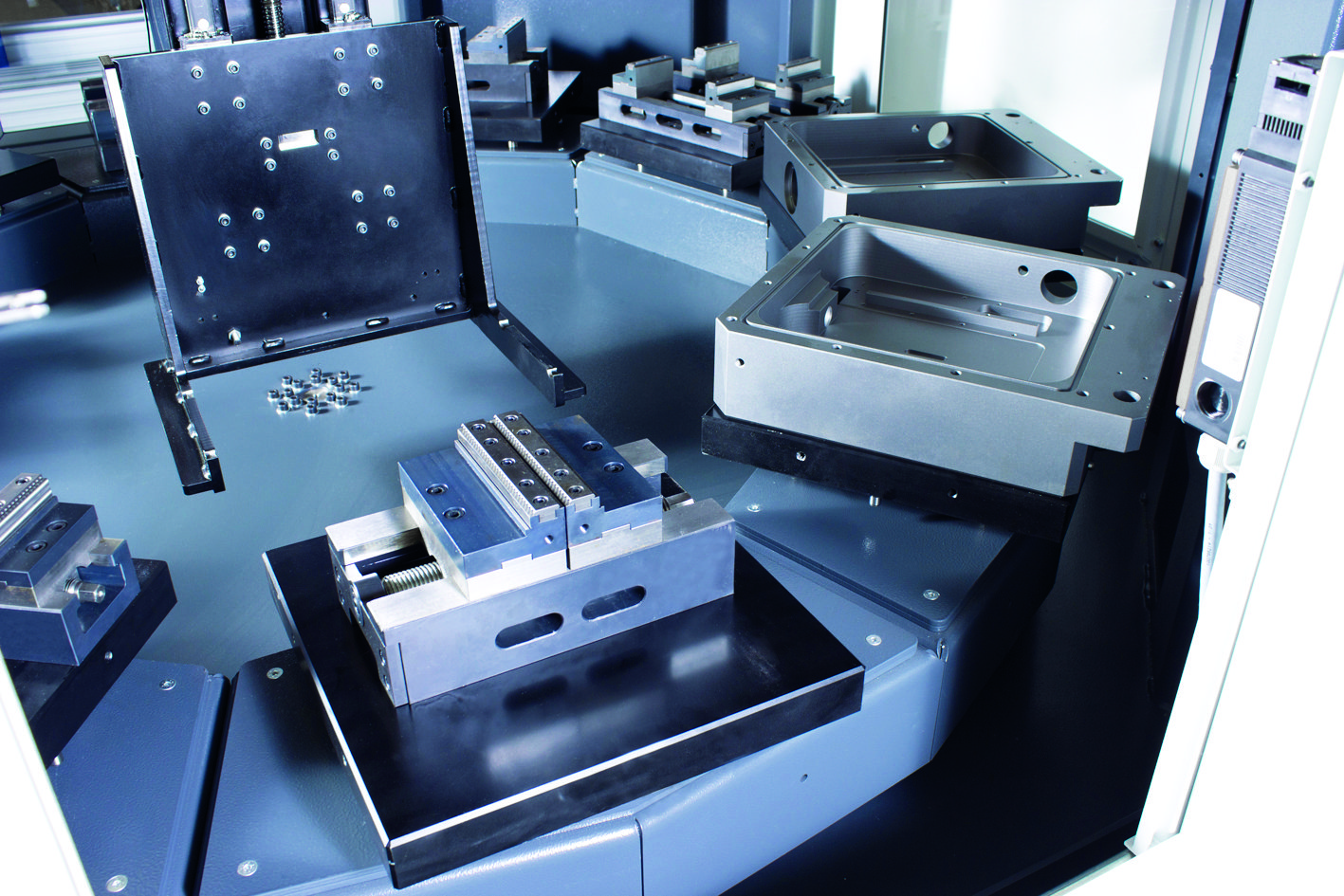

For multi-sided machining, numerous standard rotary

tables in single- or two-axis versions as well as special

fixture bridges, even with multiple clamping, are available.

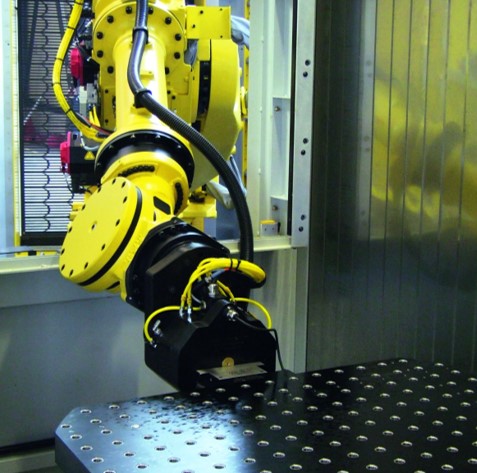

For automation, usually fast robot systems are used.

If required, theses systems can also take on auxiliary

and additional tasks such as brushing, deburring,

washing and marking in a cost-effective manner. Automation

principle optionally with pallet or workpiece

handling – or both.

Do not hesitate to contact us.

MATEC 30SHV

- Swivel table

- Swivel head ± 105°

- X-/Y-/Z-axis 2,000/600/800 mm

Multi-sided or end machining on long workpieces with a

length of up to 800 mm

Automation sample: MATEC 30SHV

Plant interlinked in a line with upstream and downstream

process steps.

3-sided machining of profiles. MATEC manufacturing

cell with loading and unloading during machining

operations.

Additional processes: deburring, washing and drying at

the loading station.

Automation

- 6-axis robot

- 2 x drawer-type magazine with six drawers

- Drawers can be loaded externally

- Alignment and positioning station

The arrangement of the robot in front of the machine

guarantees free access to the loading station even for

set-up and manual loading.

View or the work areas with the safety partition wall

at the centre of the swivel table open. 6-axis robot in

unloading position.

Two workpieces clamped in each work area. Machining

of both ends by means of swivel head.