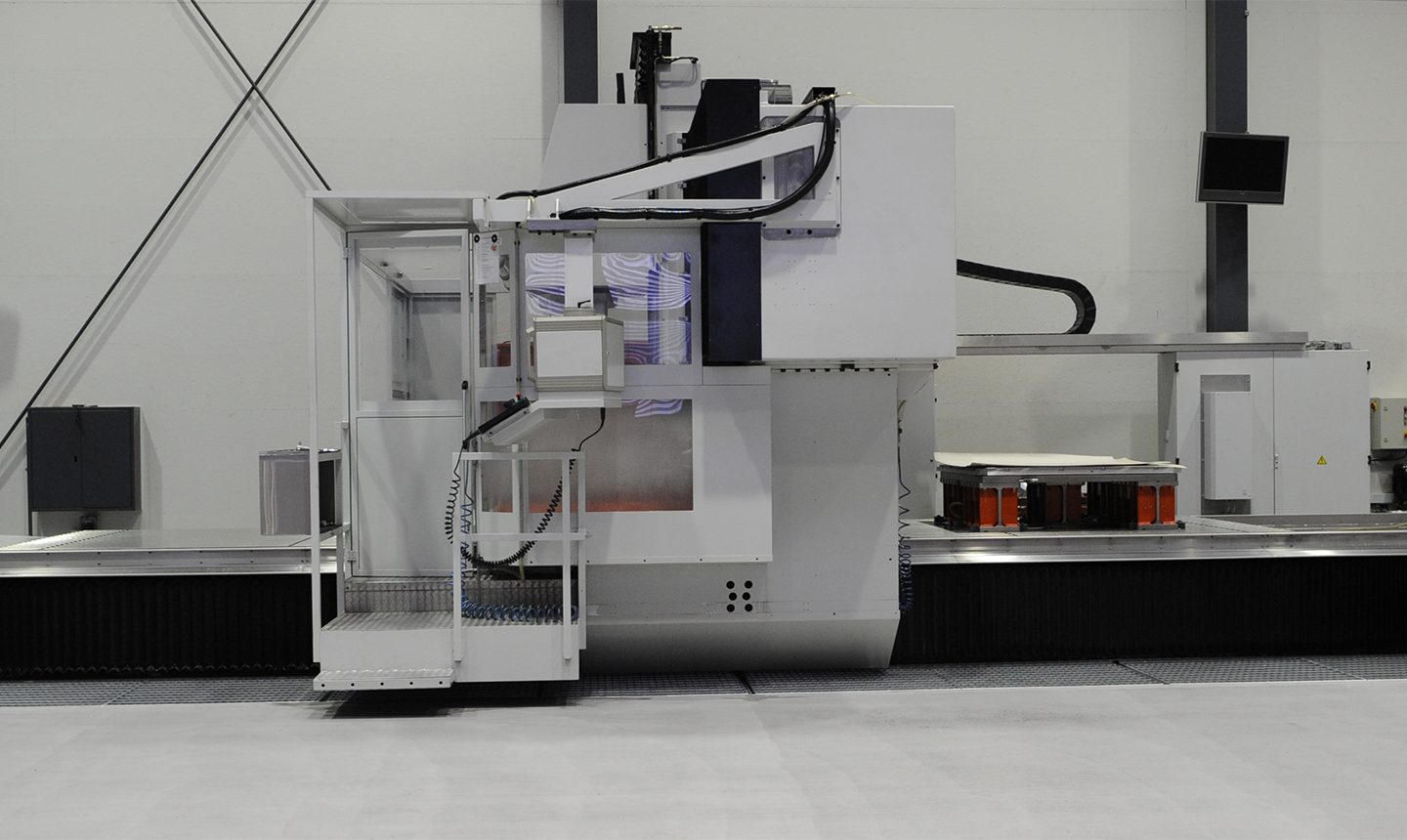

MATEC 30P - Gantry machines, which touch engineers' hearts

Excellent large part production

MATEC 30P is a gantry machining center with 2-axis CNC swivel head

for 3D machining. The machine has been developed for tool and mold

production and meets highest quality requirements. The well

dimensioned gantry construction warrants minor deformation

of the machine and there-fore contour constancy and surface quality

of the work part. Exhibiting stability and surpassing chipping perfor-

mance, this machine concept can be applied in machine and welding

industries.

Technical Information

- Performance Class SK40|HSK-A 63

- X-Axis = 3,000-12,000 mm

- Y-Axis = 2,500|3,000|3,500|4,000 mm

- Z-Axis = 1,100|1,300|1,500|1,800 mm

- Speed Range: 9.000-42.000 rpm

- Drive Power Motor Spindle: max. 30 kW

- Torque max. 191 Nm

Benefits

- Compact gantry center with minimum floor space in relation to the available

working space dimension - Stationary machine table and moving gantry enable highest workpiece weights.

All axis movements are made by the machining tool executed. Different work-

piece weights have no influence on machine dynamics and precision - The dynamic 2-axis fork head ensures strong construction at maximum feed

force and at the same time guarantees the expected surface qualities on the

workpiece. Both heads have direct measuring systems and selectable clamping. - A special feature of all MATEC gantry machines is the enormous rigidity of the

individual axes. Specifically, the design and stability of the Y and Z axis are

essential for precision and surface quality on the workpiece. The special

dimensioning of the gantry beam prevents the gantry beam torsion that other-

wise occurs on comparable gantry machines when the Z-axis is fully extended.

The Z-axis is designed as a carriage. - Due to the constant distance between carriage guide and spindle nose in

- contrast to the RAM construction, there is no movement-dependent

deformations of the Z axis. This construction is the guarantor of aligned bores

and free milling surfaces on the workpiece. - Traveling tool magazines in the X-axis enable short tool changing times.